Servo motors play an important role in an industrial automation system and give a high degree of control on the position, speed, and motion. They have extensive application in robotics, conveyor systems, CNC machines and packaging machines. Servo motors help to increase the productivity, minimise the errors, and increase the general efficiency due to execution of the motion that is correct and repeatable. In the case of industries that are constantly in operation, it is important to know the advantages of such motors, as well as their maintenance requirements, such as the servo motors should be repaired in time to avoid being down.

Accuracy and savings in Automation

Servo motors have one of the main benefits of being able to offer an accurate positioning and control of speed. In automation of industries, the slightest variation can cause a mistake in production or wastage of materials. Servo motors enable machinery to move like clockwork, so that there is uniformity in quality and minimal chances of mistakes. These motors also help to increase the efficiency of operation when they are well maintained to minimize energy waste and also to maximise workflow throughout the factory floor.

Plasticity and Changeability

Servo motors are universal and they can be programmed to fit certain operational needs. They can be used in high-speed production lines and they can also be used in delicate assembly operations. This flexibility enables the manufacturers to change production configurations or modify equipment without significant re-structuring. Periodic maintenance of the servo motor is a way to ensure that these systems are always operational to serve dynamic industrial operations and reduce unplanned downtimes.

Prolonging Life of Equipment and Wear

Servo motors are engineered to deal with precise loads and this minimizes unwarranted mechanical component wear. This exact control is translated into the less stressful running and the reduced stress on gears, belts, and other moving elements. Nevertheless, the constant working of the industry may ultimately result into wear in the motor itself; hence, routine checkups and servo motor repair is important. Maintenance will ensure that little problems do not grow bigger since timely maintenance will extend the life of both the motor and the machinery to which it is attached.

Automation Systems Interaction

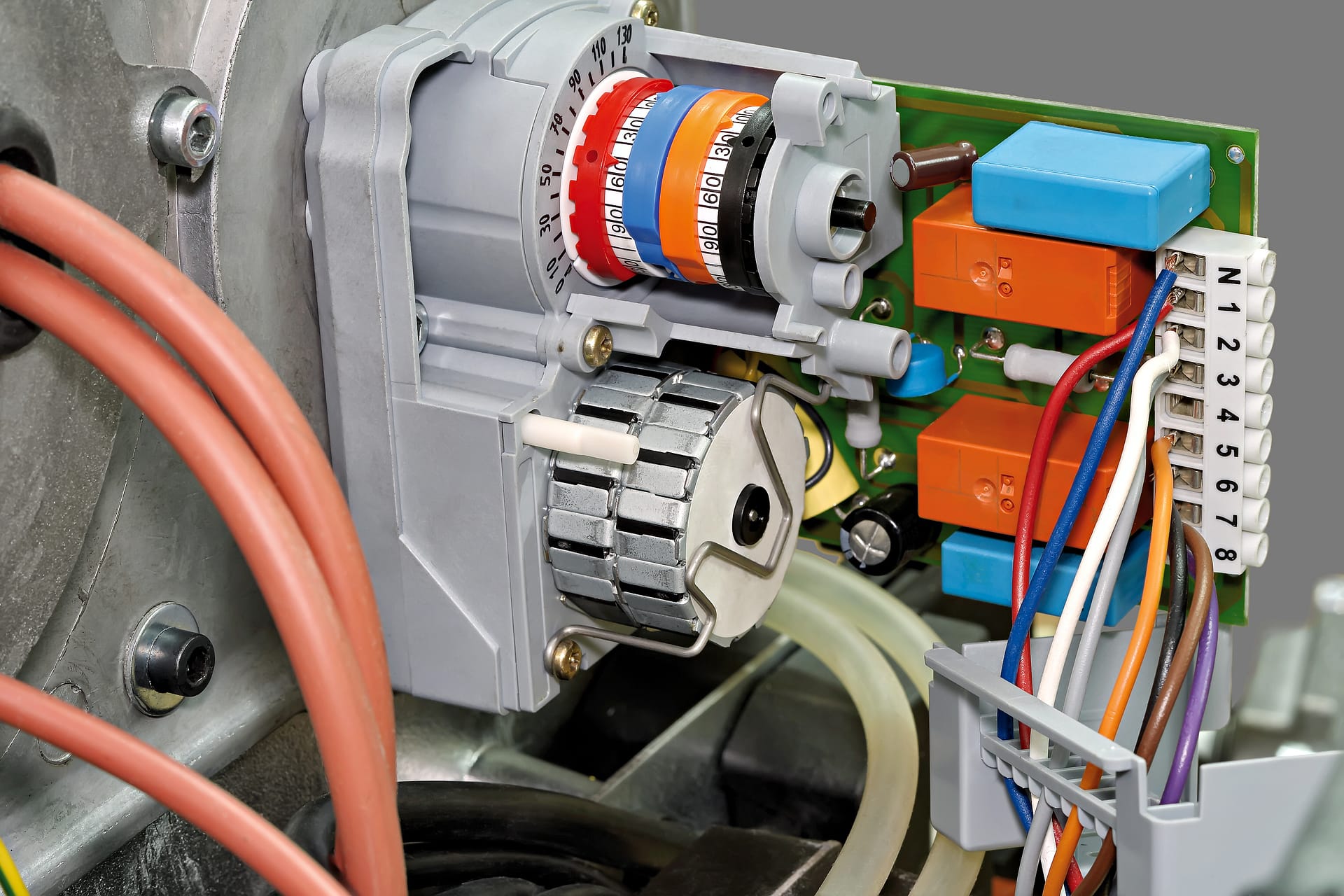

Servo motors are easily integrated with controllers, sensors and feedback systems to become the foundation of the new automation. The encoder or resolver feed allows the motor to correct and make real-time adjustments to the motor to keep it operating correctly. This closed loop system is necessary in complex industry applications where no one deals with issues of precision and consistency. With the constant servo motor repair, these feedback systems will stay transparent, high automation reliability rates are maintained.

Reducing Unproductive Time and Wastage

Any failure in the motor may stop the production lines which will result in high cost of downtime and delay. Maintenance schedules and timely servo motor repairs contribute to the detection of the possible troubles in advance before they lead to breakdowns. The constant optimum motor performance will ensure that manufacturers do not experience unplanned interruptions, and the production process will be carried out smoothly and fulfill the deadline.

Final Thoughts

Servo motors have become essential in industrial automation in the present day, with the benefit of precision, flexibility and efficiency. They have a direct influence on the productivity and reliability of machinery, and therefore maintenance and qualified servo motor repair are necessary. With the correct maintenance and repair, industries will be able to benefit the most out of servo motors, which will lead to the seamless functioning of the industries and the increase of the life of automation systems used in the industries.